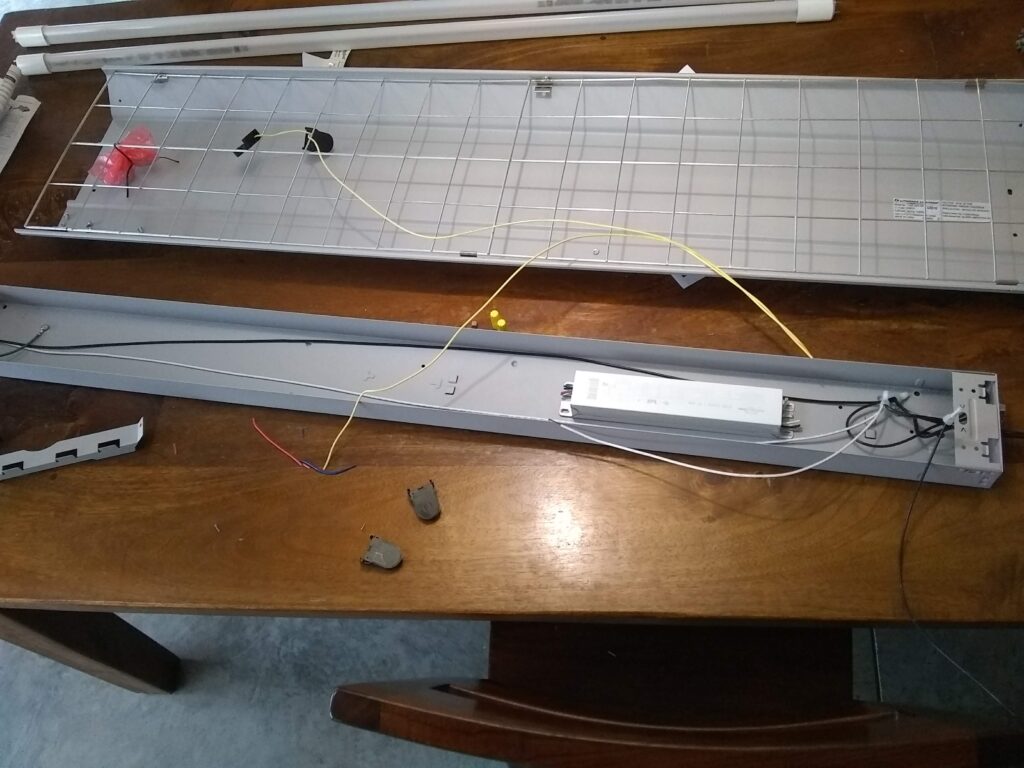

I usually start our seeds indoors and get our garden plants started about 4-6 weeks before the last frost date here in Rochester which is May 15th. While we do get some awesome light through our large south facing windows during the winter months, once spring arrives our large overhangs starts to limit how much direct sunlight seedlings would get during the day. In addition window light tends to make the plants leggy and not straight as they bend towards the window. Our first solution is indoor grow lights. We built a two shop light growing area that would fit in one of our closets.

The grow light system works well but there is limited space and the plants then have to be “hardened off” before they can survive outside. Hardening off is the process of acclimating your plants to the outdoors so they can survive sun, wind, cold, and other elements they weren’t exposed to while growing indoors. Often if not done correctly taking the seedlings outdoors can kill the plants.

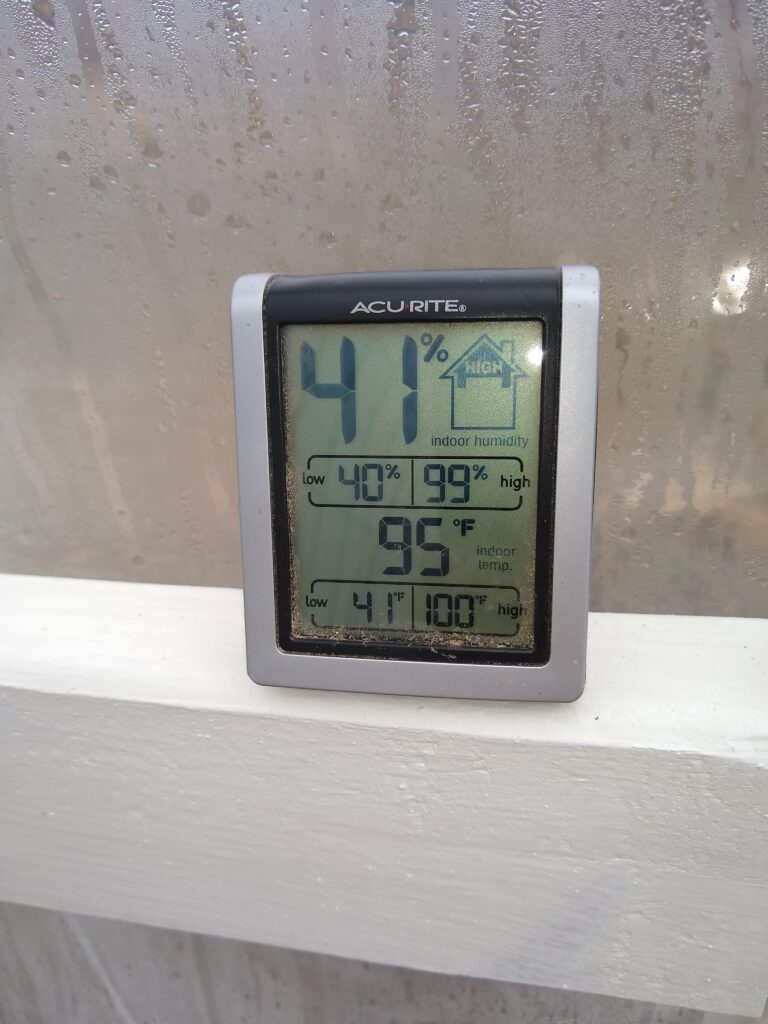

So I wanted to build a mini greenhouse where I could grow many of our seedlings prior to our last frost date of May 15th and come up with a plan on how the plants would survive if the temperature did drop towards freezing at night. We combined a cattle panel greenhouse which is popular on gardening videos and straw bale gardening which was recently proposed as a novel heat source for mini greenhouses.